About Us

Chemical Cleaning

Tank Cleaning

SKDPL presents "SORU" a self contained oil...

Coating Against Corrosian

SKD PROVIDES Saekaphen COATING IN India on...

Chemical Cleaning

Sri Krishna Descalers ( SKD) , Specialists in the...

Capicity

Sri Krishna Descalers Pvt. Ltd. can Undertake jobs of any volumes and we can give a flow rate of up to 2500 m3/hr.

Tank Cleaning

SKDPL presents "SORU" a self contained oil...

Coating Against Corrosian

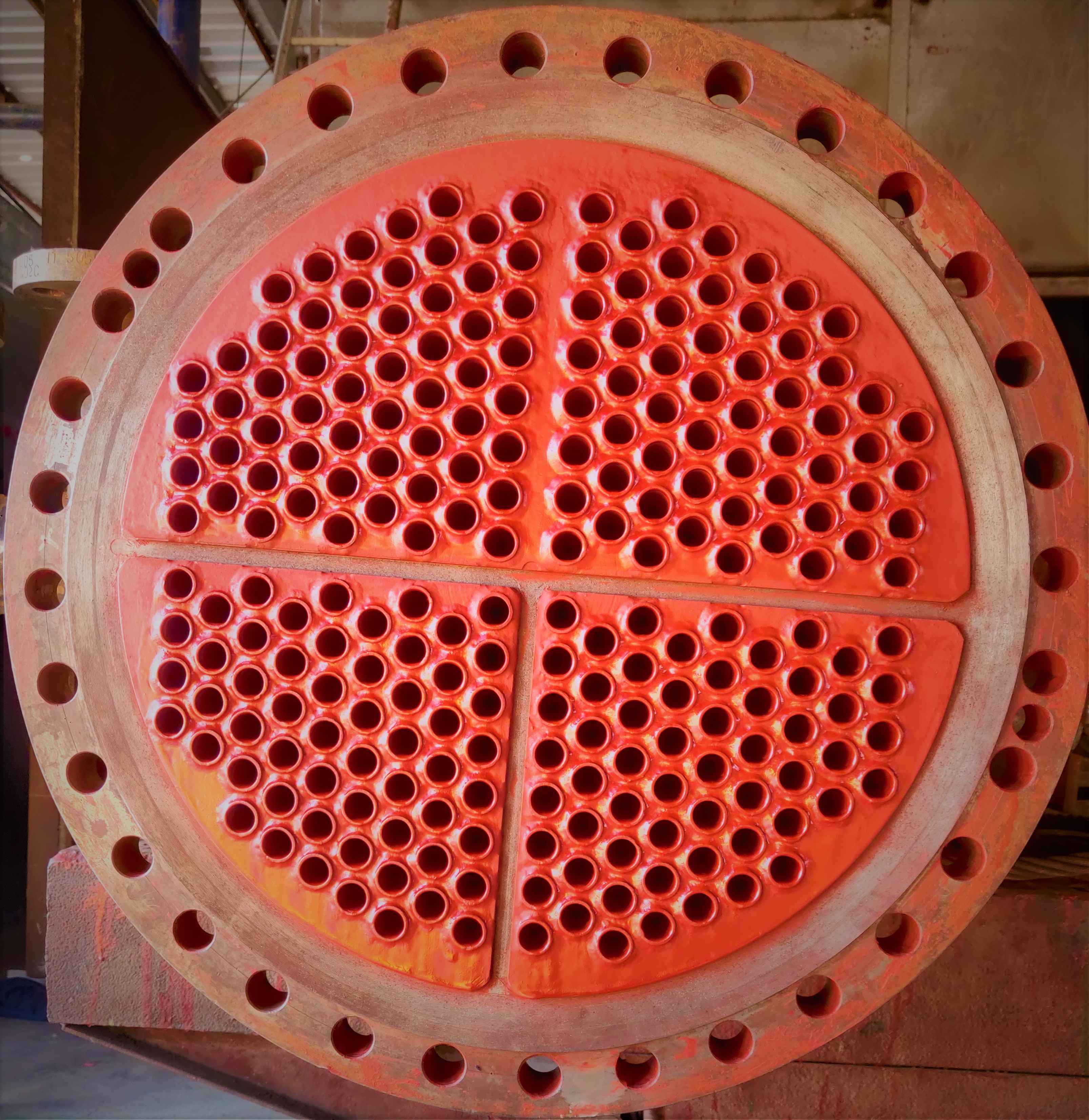

SKD PROVIDES Saekaphen COATING IN India on...

Chemical Cleaning

Sri Krishna Descalers ( SKD) , Specialists in the...

Infrastructure

BARODA, JAMNAGAR & SURAT

SKDPL Factory of 34000Sq ft at Manjusar Baroda with all necessary machinery and infrastructure for coating & Chemical Cleaning

6500 Sq.Ft of Residence and Godown at Meghpur -Jamnagar - catering to M/s. RIL - Nyara

1500Sq Ft Property In Surat for serving M/s. RIL – Hazira

Tank Cleaning

SKDPL presents "SORU" a self contained oil...

Coating Against Corrosian

SKD PROVIDES Saekaphen COATING IN India on...

Chemical Cleaning

Sri Krishna Descalers ( SKD) , Specialists in the...

Quality

ISO 9001 : 2015 Certified, Certificate Number : QM 02 01446 Quality is based on Agreed Procedures and Testing of process with Clients based on needs Equipment’s are Calibrated and Testing is done by Professionals during Process Staring from a simple Thermometre / UV lamp / Boroscope all are from reputed suppliers Coating Equipmets have the best Testing equipment’s approved by German Standards Our clients repeated orders over the years speaks on the quality of job executed , please check our clientele list Our growth has been based on Quality and Timely Service ASTM/ ISO STANDARDS are used for Chemical Cleaning and coatings

Tank Cleaning

SKDPL presents "SORU" a self contained oil...

Coating Against Corrosian

SKD PROVIDES Saekaphen COATING IN India on...

Chemical Cleaning

Sri Krishna Descalers ( SKD) , Specialists in the...

Our Valuable Clients

Frequently Asked Question

NO SKDPL GURANTEES that none of the Chemicals used by it can Corrode the MOC.

Yes any Type of Scale can be removed including SILICA SCALE

Chemical Cleaning is done INSITU . Hence only dropping of Inlet/Outlet valve is required .

1.Volume of the Equipment 2. Height of Equipment 3. Inlet / Outlet Size 4. Water/ Steam and power availability near the equipment 5.test answer

Both Inside and outside of the Tubes to prevent Scale Formation as per customer requirement.

1.Volume of the Equipment 2. Height of Equipment 3. Inlet / Outlet Size 4. Water/ Steam and power availability near the equipment 5.test answer

NO THERE WILL BE NO CHANGE in the HEAT TRANSFER (Refer Graph in Brochure).

NO THERE WILL BE NO CHANGE in the HEAT TRANSFER (Refer Graph in Brochure).

SAEKAPHEN COATINGS removes the usage of costly MOC

SAEKAPHEN COATINGS work from–20*C to 180*C . IT can withstand both organic and inorganic chemicals.

SAEKAPHEN COATING jobs will be done only at SKDPL – Factory at Baroda